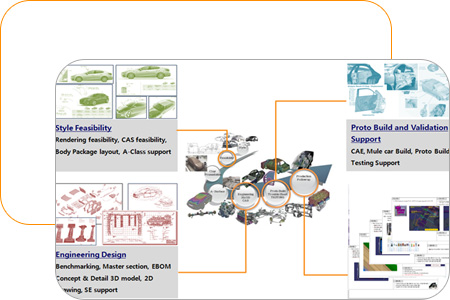

Engineering

mass production and satisfy customer requirements.

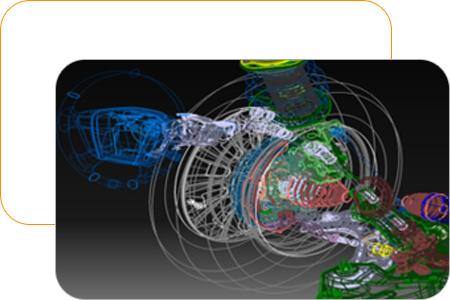

ALTEN KOREA is developing and using advanced designs and verification procedures that utilize VR systems.

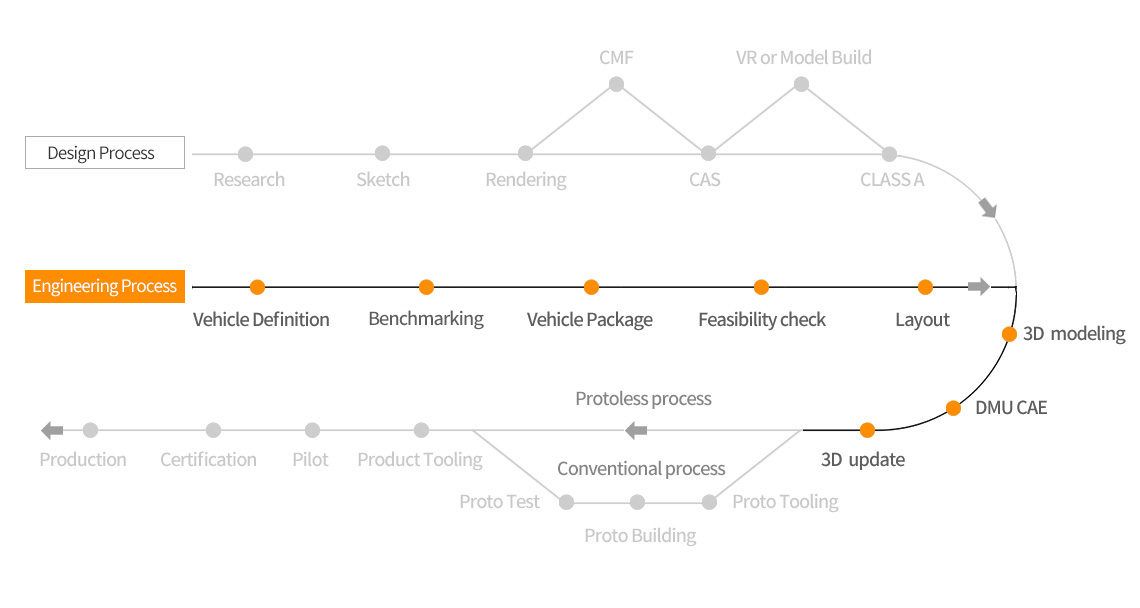

Engineering Process

Step 01. Vehicle Definition

Establish directions and product concept for new car development

- Segment

- Body Style (N/B, H/B, SUV…)

- 2WD/AWD/FWD

- Initial Dimension

- Implementation plans for key systems (P/T, Chassis…)

- New System implementation plan

Design Image development

- Idea Sketch

Establishment of development objectives

- Target Markets

- Safety Targets

- Performance Targets

- Mass & Cost Targets

- Target SOP Timing

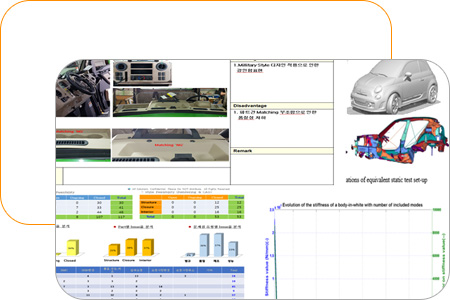

Step 02. Benchmarking

Reference & Completive Car Tear-down Analysis

- Design Analysis

- Mass & cost Analysis

- Highlight Item Analysis

- Manufacturing Engineering Analysis

- BIW Bending/Torsion Test & Modal Test

- Typical Section

Virtual Benchmarking

- 3D Scanning & Digitizing

- 3D Motion / Analysis

- Package & Layout Analysis

- Key System analysis

Step03. Vehicle Package

Initial Package Drawing

- Vehicle Key Dimensions

- Occupant Positioning & Packaging

- Coarse Sections Study

- GA Drawing Release & Up date

System Lay-out configuration

- Carry-over Apply System Review

- New Major System Selection and System Integration

Concept Section

- Suggest Reference : Master section

- Engineering Feasibility check

Step 04. Feasibility Study

Legal Feasibility

- Review of related legislation in country of sale ex.) Pedestrian Protection

Market/Planing Feasibility

- customer and market requirements, and product planning requirements ex.) Market Analysis, VOC

Engineering Feasibility

- Verification of customer and in-house design requirements

- Package confirmation that review feedback is reflected in final design

- Confirmation of satisfaction of mass production requirements and gap/offset conditions ex.) Approach Angle

Manufacturing Feasibility

- Confirmation that mass production requirements are satisfied

- Confirmation that mass-production component supplier/tooling vendor requirements are satisfied, e.g., Side Outer Draw Depth

Step 05. Layout

Engineering Requirments

- Package Requirements

- System Lay-Out

- New PT installation Requirements

- Design specification Concept, construction method, performance determination

- Mass , Cost Targe

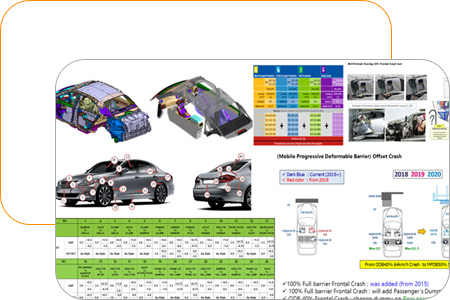

Market Requirements

- Domestic and overseas customer requirements and trends

- NCAP requirements according to area of export

- Requirements for improvement of currently produced vehicles

Legal Requirements

- Collision safety laws in each country (head-on collision, side collision, pedestrian safety-related laws, etc.)

- Environmental regulations for emissions gases and noise

- Verification of potential to meet regulations relating to the recovery of recyclables

Manufacturing Requirements

- Conformance with in-house mass production requirements

- Due consideration of processes/methods of key suppliers

- Reflection of work environment improvement requirements, including work posture

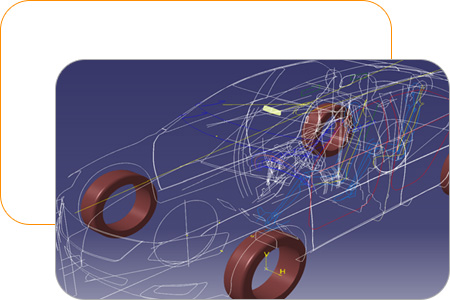

Step 06. 3D Modeling

Initial skin data, master section and initial package drawing used to prepare system 3D data to meet market, engineering, legal and mounting requirements

Preparation of 3D data with consideration of gaps/offsets

CAS and Class-A surface data finalization followed by 3D data update

3D data reviewed based on client-designated tooling maker and specifications prior to distribution

Basic data for CAE analysis

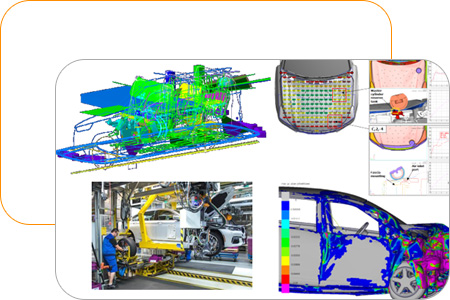

Step 07. DMU CAE

Verified using virtual simulation for shorter development period and cost savings

- Crashworthiness

- DMU

- FMH

- Pedestrian protection

- Luggage Intrusion Analysis

- Structural Stiffness Analysis

- CFD Analysis

Verification using DMU (Digital Mock Up)

- Design quality verification and component clearance/interference check

- Early verification of assembly performance, workability and ease of maintenance

Step 08. 3D update

Client requirements

- Reflect requirements such as design concept, target weight, and performance.

Legal and NCAP Follow-up

- Market requirements review and design reflection

Performance

- Performance verification and design reflection through CAE

Manufacturing

- Mass production verification and design reflection through SE

Design Optimization

- Design Review and Design Optimize using ALTEN KOREA Deep Process